Optical

HACK SHAPES PRODUCTS FROM ALL INDUSTRIES WORLDWIDE DESIGN AND FUNCTION.

This is how our expertise enriches the daily lives of many people.

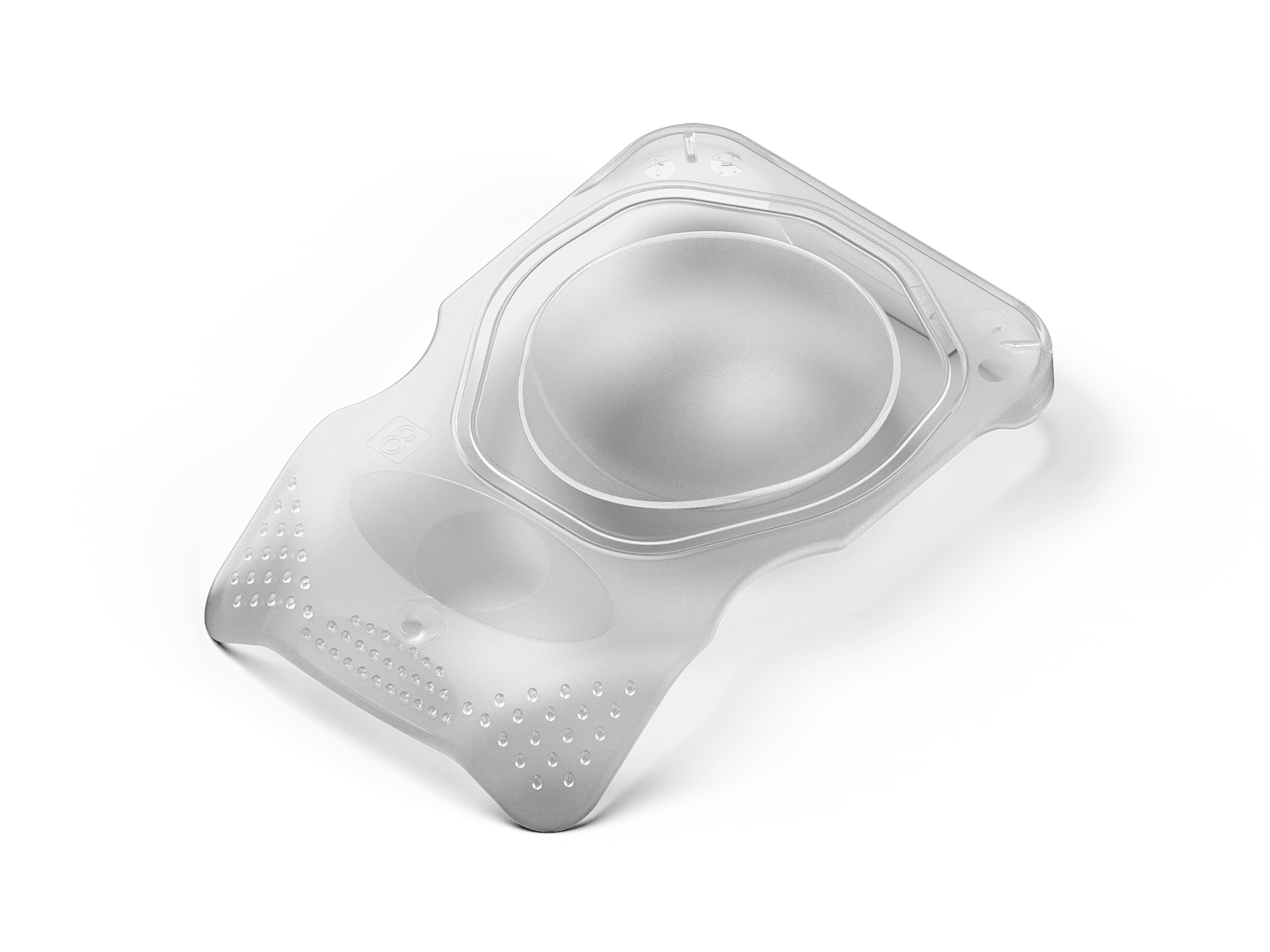

Our injection molds for the optical industry are developed with the highest level of precision and are specifically engineered to meet the demanding requirements of transparent and optically pure components. From the design stage onward, we consider all optics-specific factors—ranging from ultra-smooth, high-polishable surfaces and exceptional dimensional stability to temperature-controlled and process-optimized tool concepts that enable distortion-free and defect-free replication. Specialized coatings, high-precision cavity geometry, and particle-reduced tool layouts ensure easy demolding, long tool life, and consistently reproducible quality.

Through this comprehensive engineering approach, we serve as a strong and reliable partner for manufacturers of optical products who depend on clarity, flawless surface quality, and optical purity. Our molds are used for the production of contact lenses, optical microcomponents and transparent analytical parts. In all of these applications, they deliver maximum clarity, outstanding process stability, and consistently excellent part quality—key factors for modern, high-performance optical products.

THENextGenMOLDMAKER