Packaging

HACK SHAPES PRODUCTS FROM ALL INDUSTRIES WORLDWIDE DESIGN AND FUNCTION.

This is how our expertise enriches the daily lives of many people.

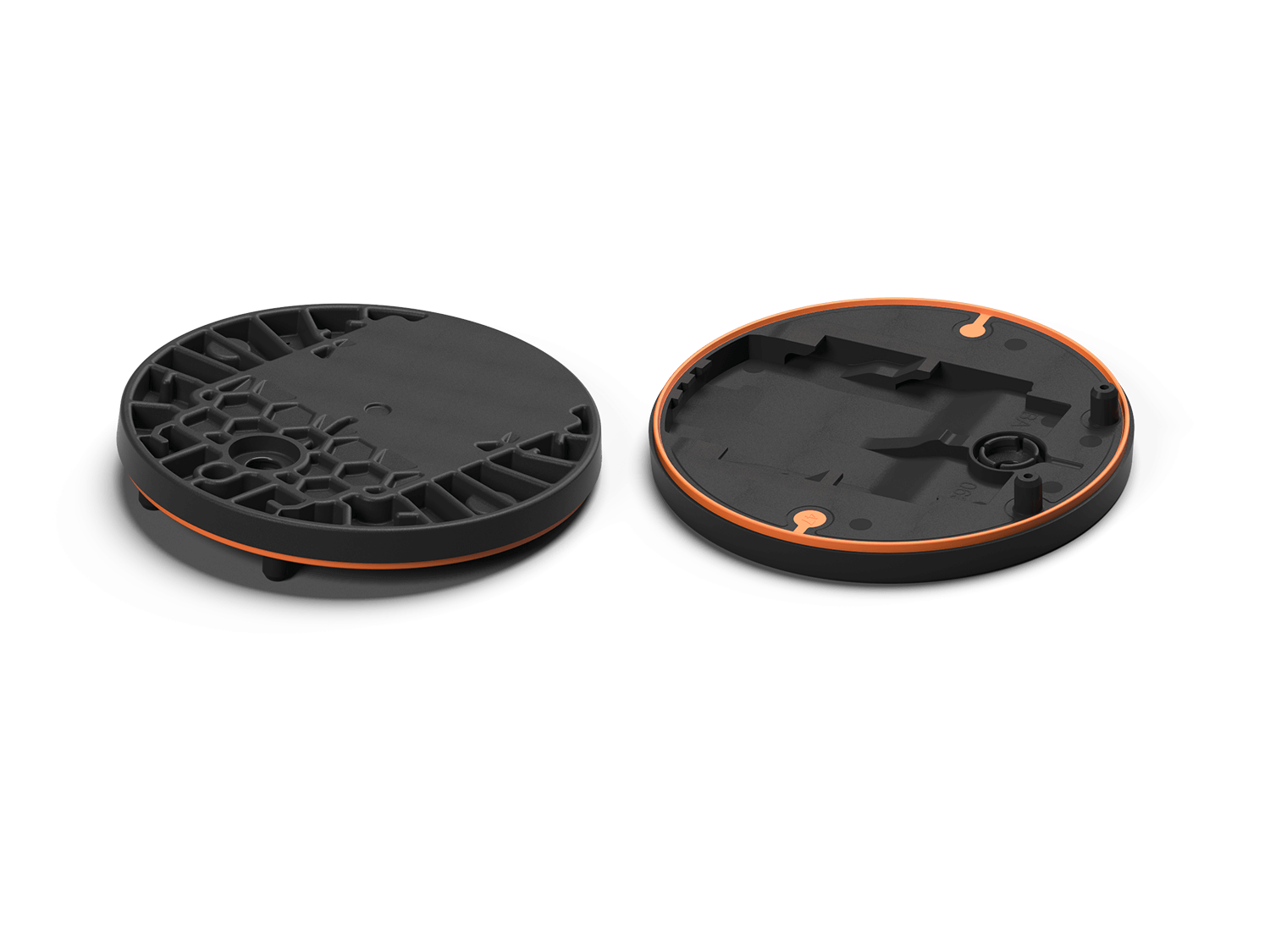

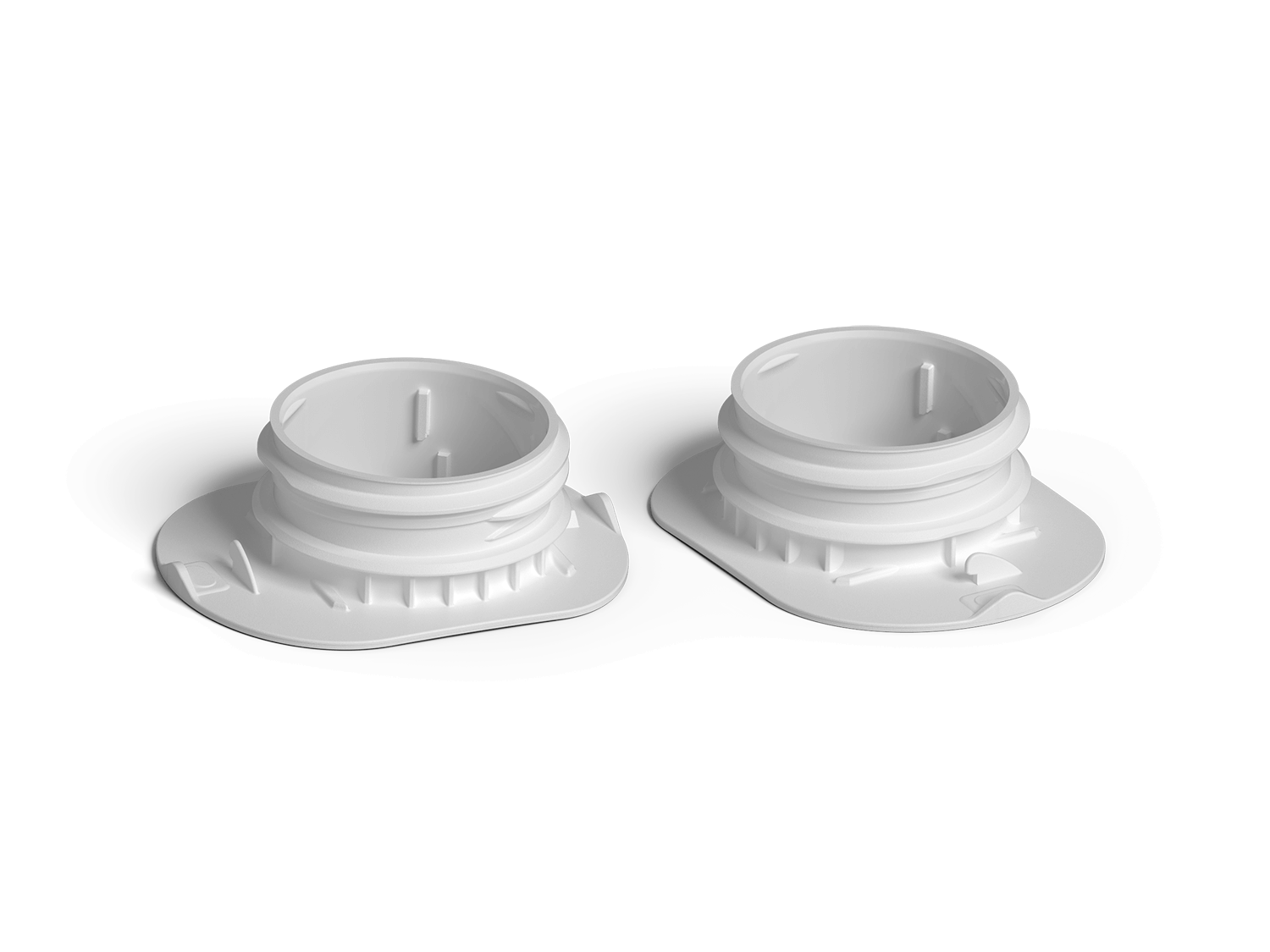

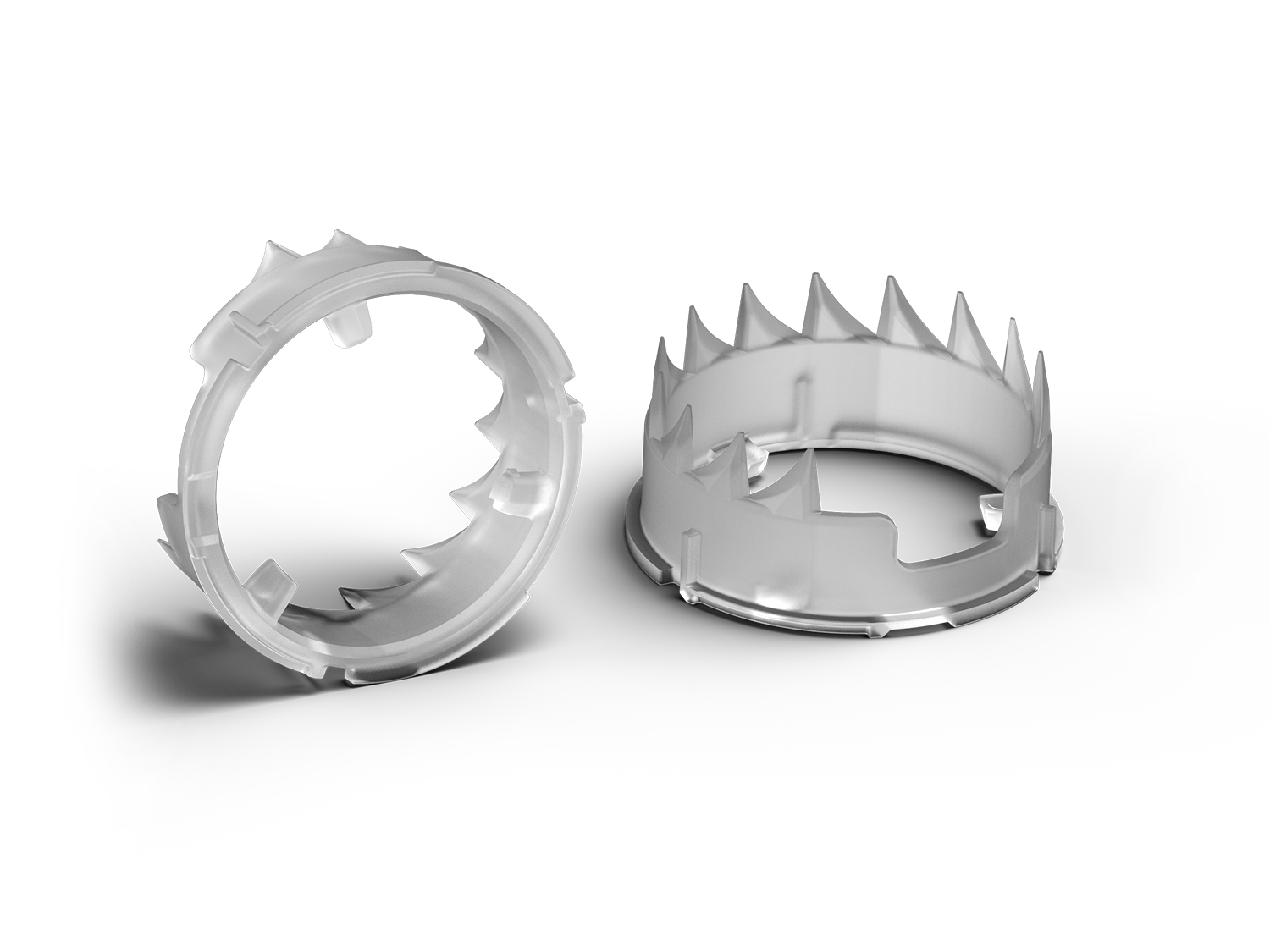

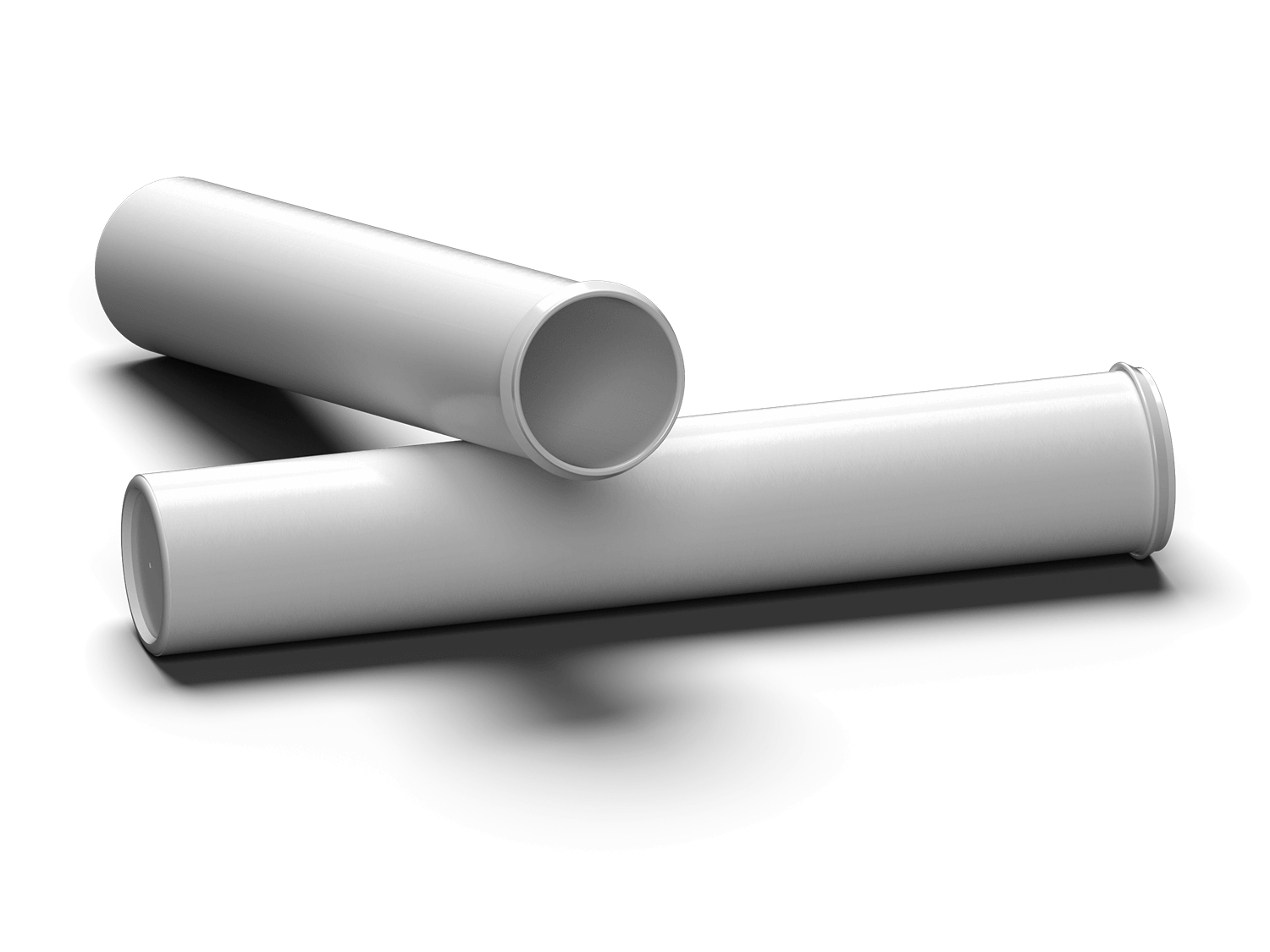

Our injection molds for the packaging industry are engineered with the highest precision and specifically designed to meet the demanding requirements of beverage closures and medical packaging solutions. From the very beginning of the design process, we incorporate all relevant parameters—materials-specific flow behavior, high-performance cooling concepts, lightweight and cycle-optimized tool designs, as well as surface qualities that ensure both functional sealing and visual appeal. Optimized cycle times, quick mold changes, functional coatings, and precisely defined tolerances guarantee efficient high-volume production with maximum repeatability.

Our molds are used extensively in the production of modern beverage closures, including screw caps, lightweight closures, tamper-evident systems, and hygienic snap-on caps. In addition, we develop highly precise mold solutions for medical packaging components, such as pharmaceutical primary packaging, protective and dosing caps, cartridge and vial components, and functional closure and sealing systems for sensitive fill goods. Across all these applications, our tools deliver robust performance, excellent surface quality, stable output, and long service life—key requirements for safe, efficient, and brand-driven packaging solutions in both the beverage and healthcare sectors.

THENextGenMOLDMAKER