PHARMA

HACK SHAPES PRODUCTS FROM ALL INDUSTRIES WORLDWIDE DESIGN AND FUNCTION.

This is how our expertise enriches the daily lives of many people.

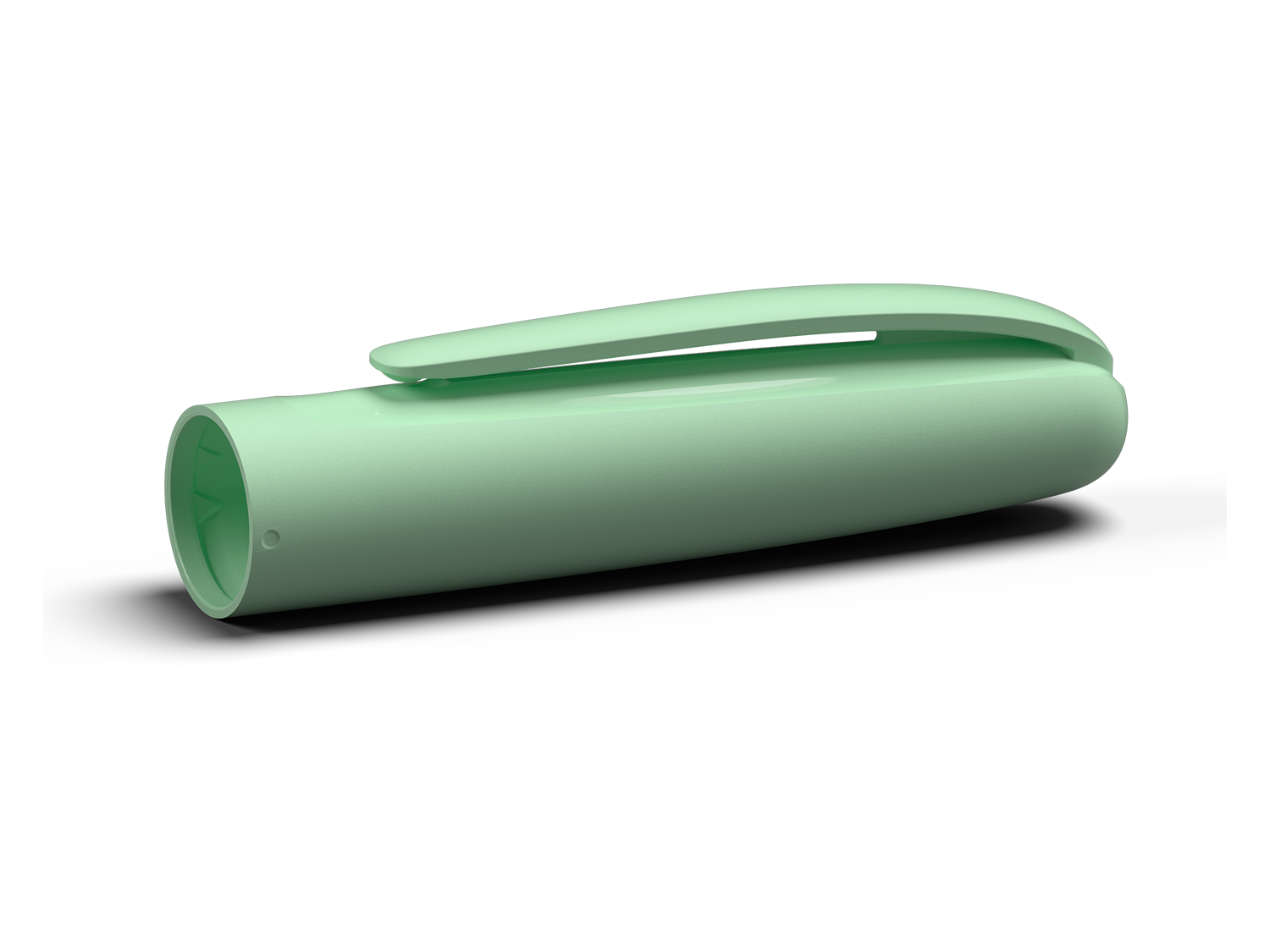

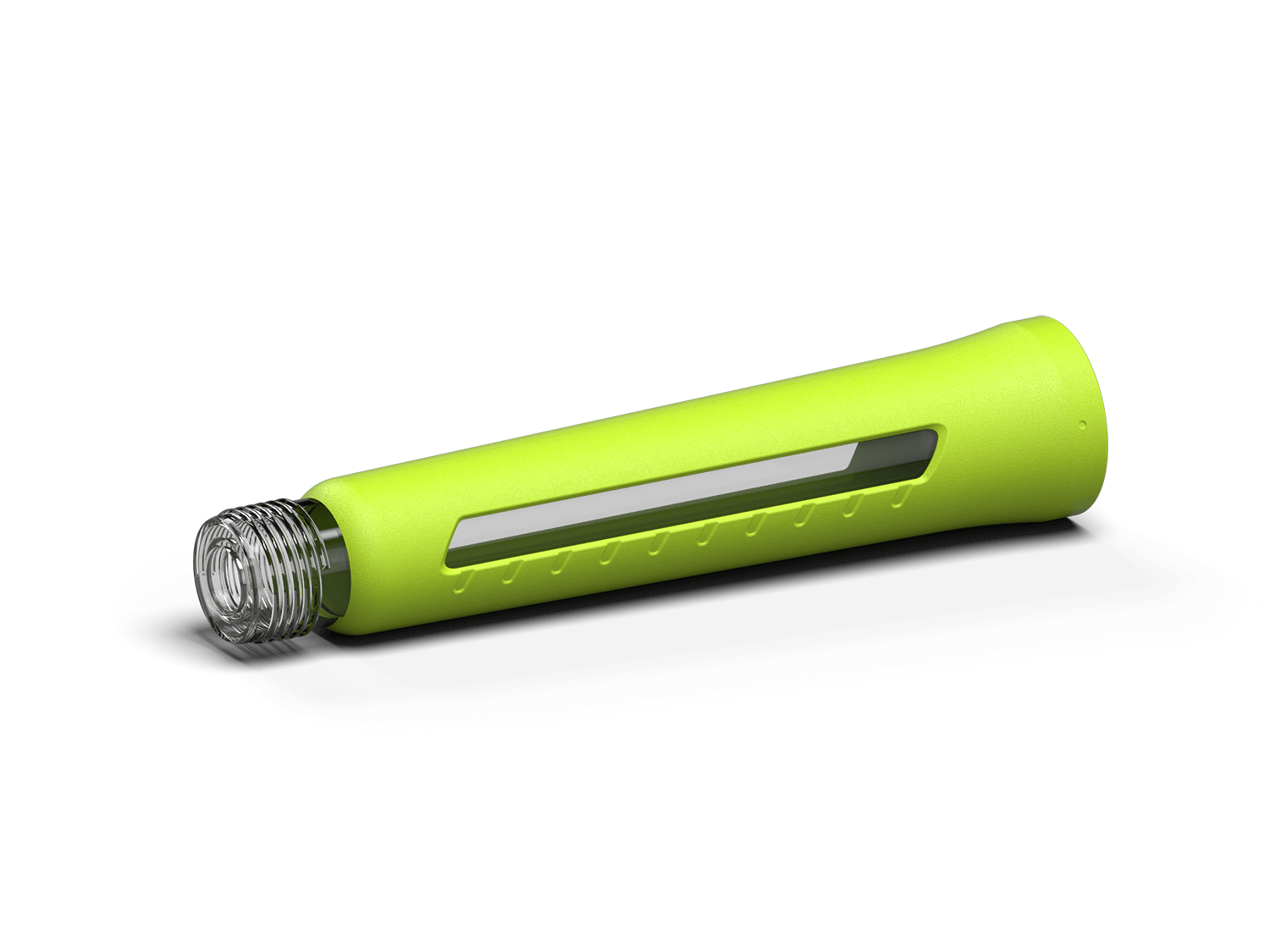

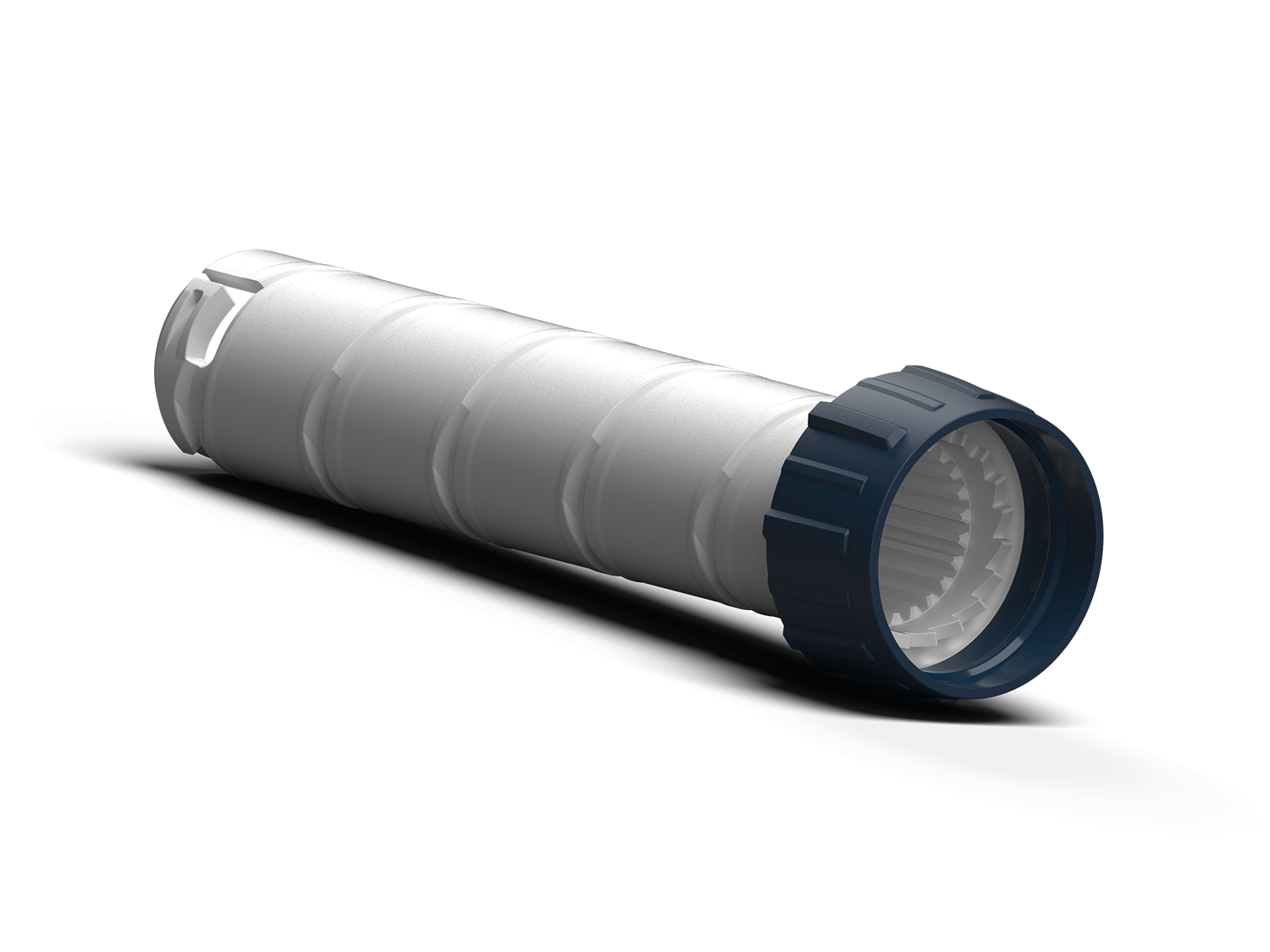

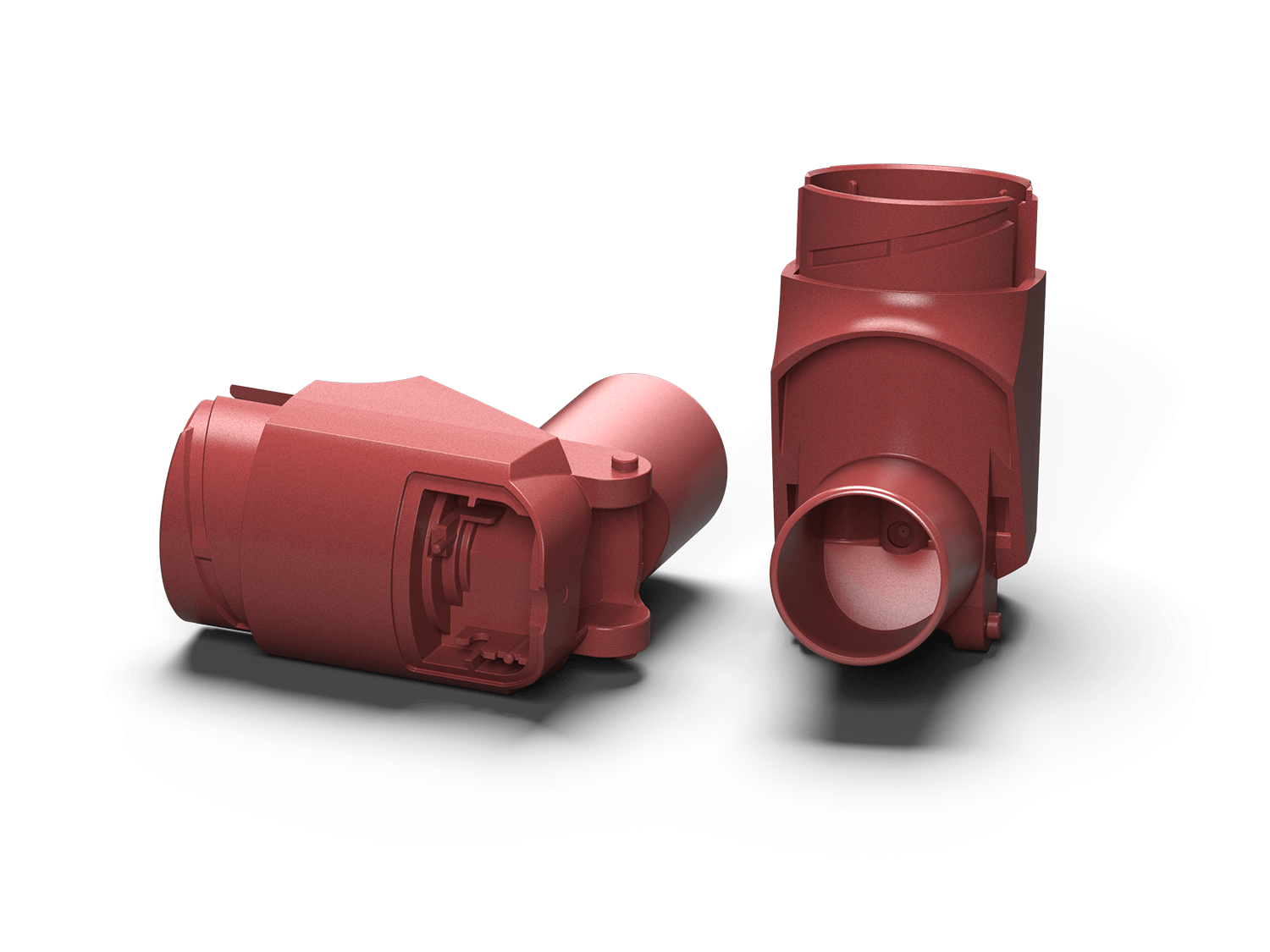

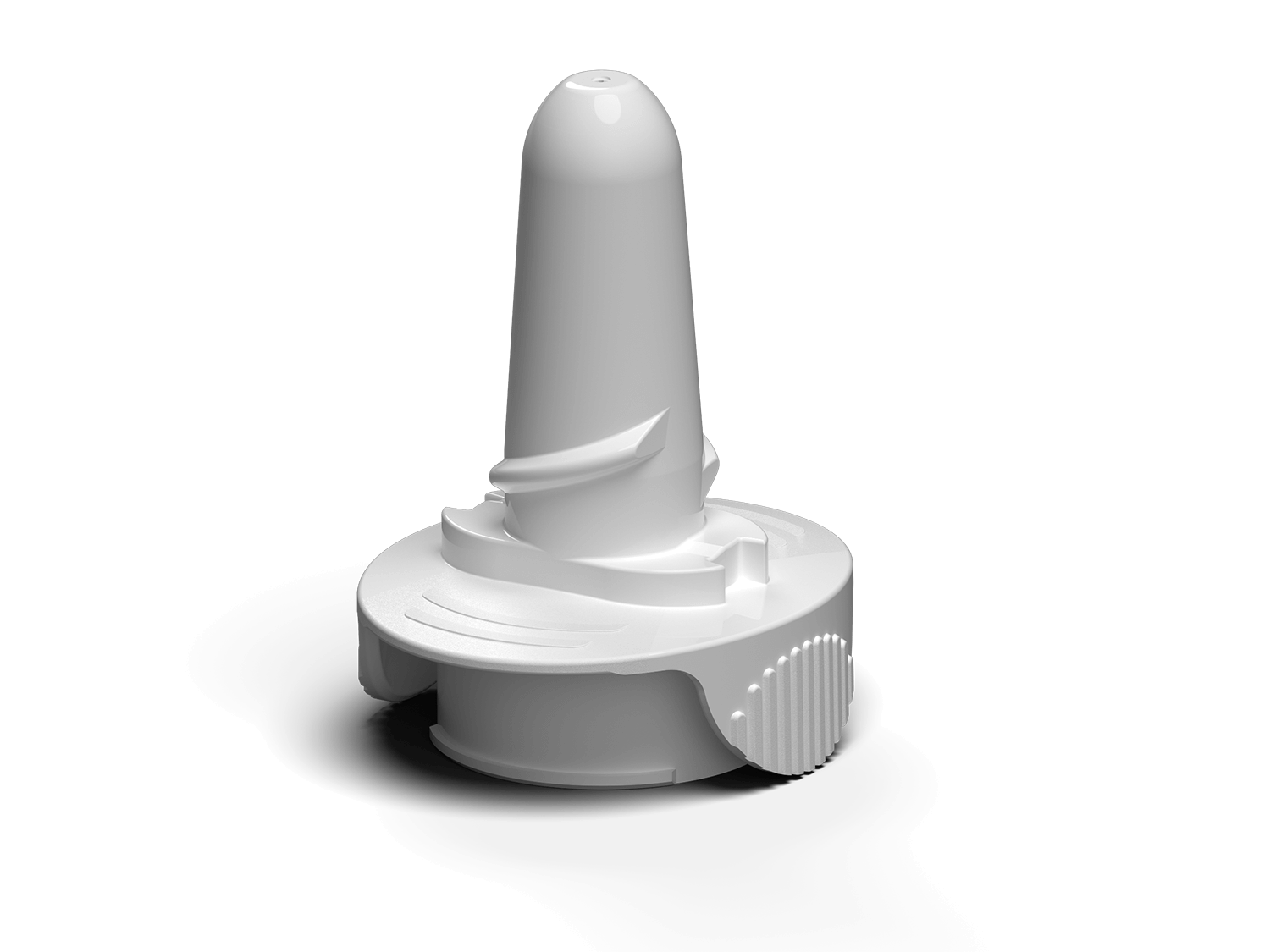

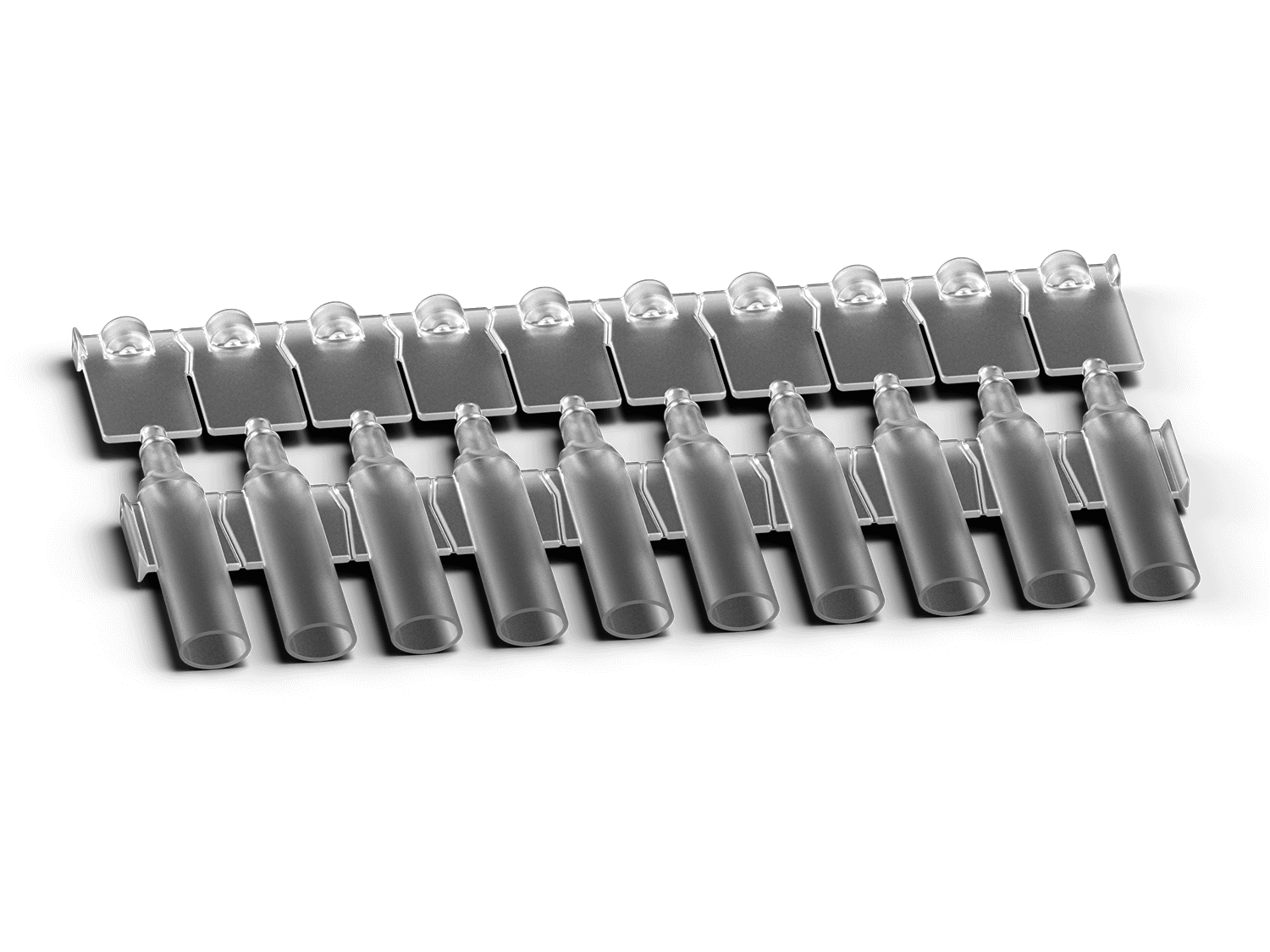

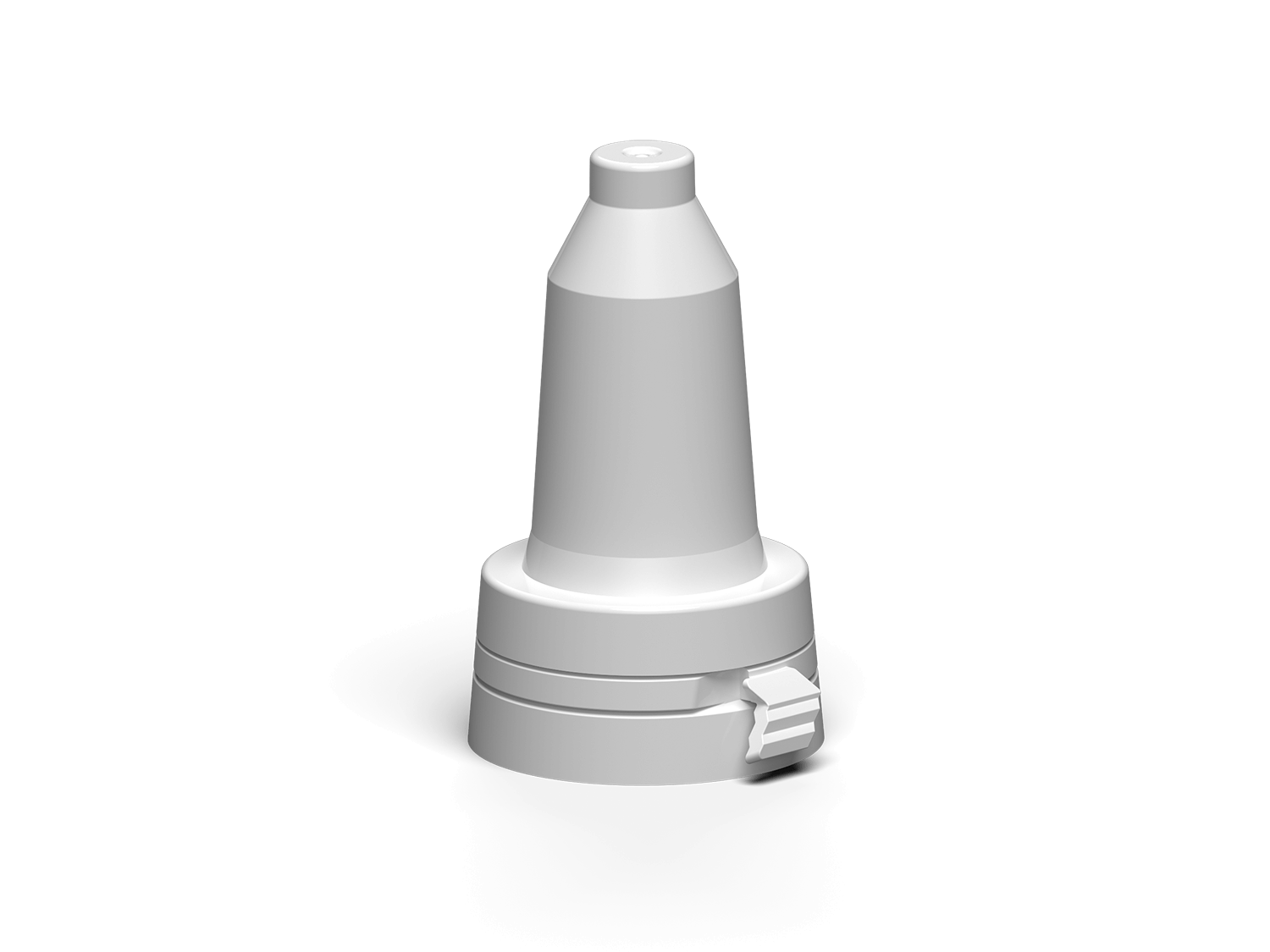

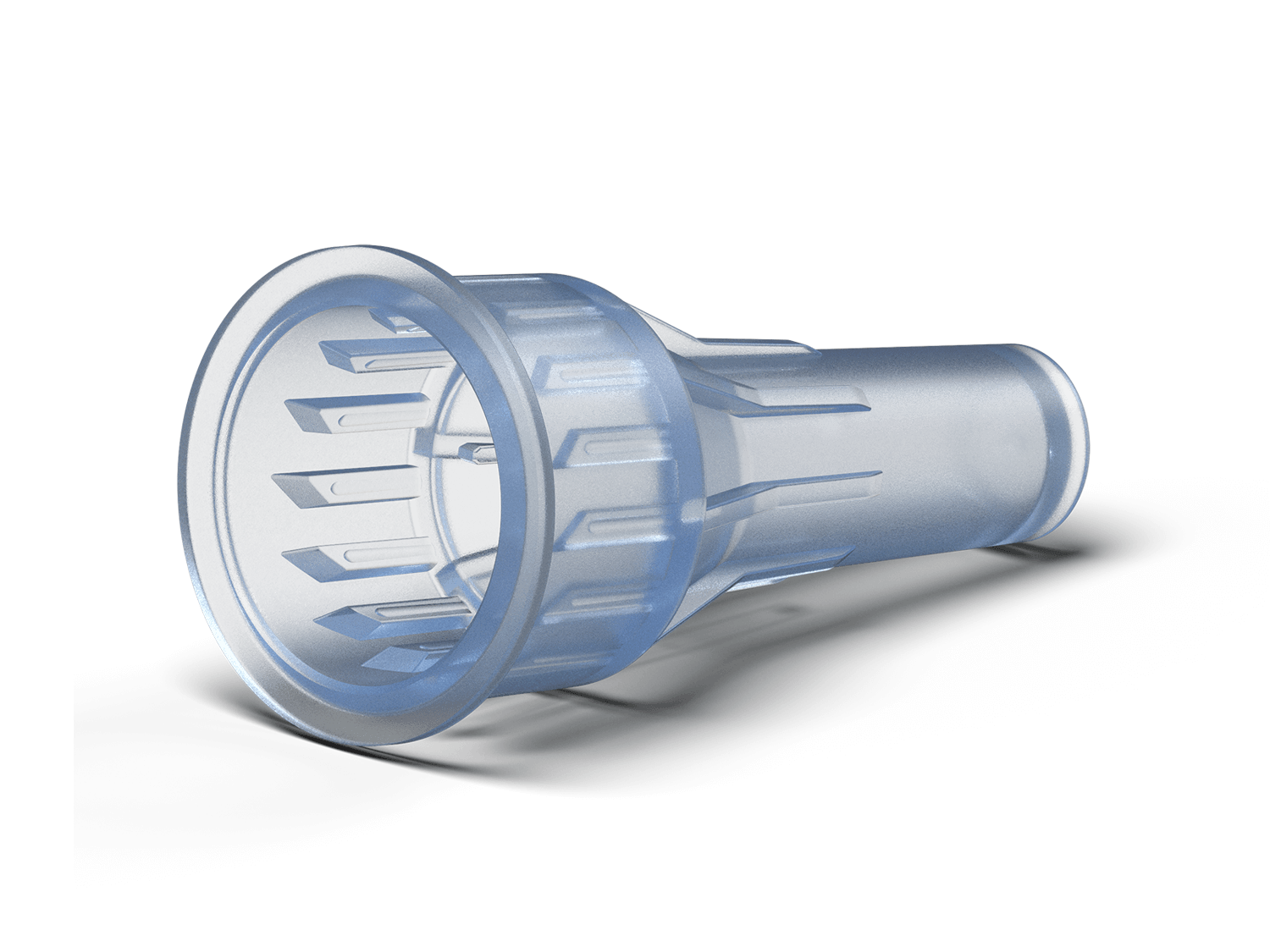

Our injection molds for the pharmaceutical market are developed using state-of-the-art technology and engineered to meet the highest regulatory and functional requirements. From the earliest design phase, all pharma-specific factors are incorporated—ranging from cleanroom-optimized and particle-reduced tool concepts to lubrication-free designs and functional coatings that ensure stable demolding, long tool life, and reliable reproducibility. The fully GMP-compliant configuration of all interfaces and processes guarantees consistently clean and contamination-free production.

With this holistic approach, we serve as a technologically strong and dependable partner for pharmaceutical manufacturers, placing product purity, regulatory compliance, and process stability at the center of our work. Our molds are used across a wide range of pharmaceutical applications, including drug-delivery systems, dosing and dispensing solutions, primary packaging components such as cartridges and plungers, as well as high-purity single-use parts for filling, transfer, and analytical workflows. In every application, they deliver maximum precision, consistent cycle stability, and the highest level of cleanliness. With essential foundations for safe and modern pharmaceutical production.

THENextGenMOLDMAKER