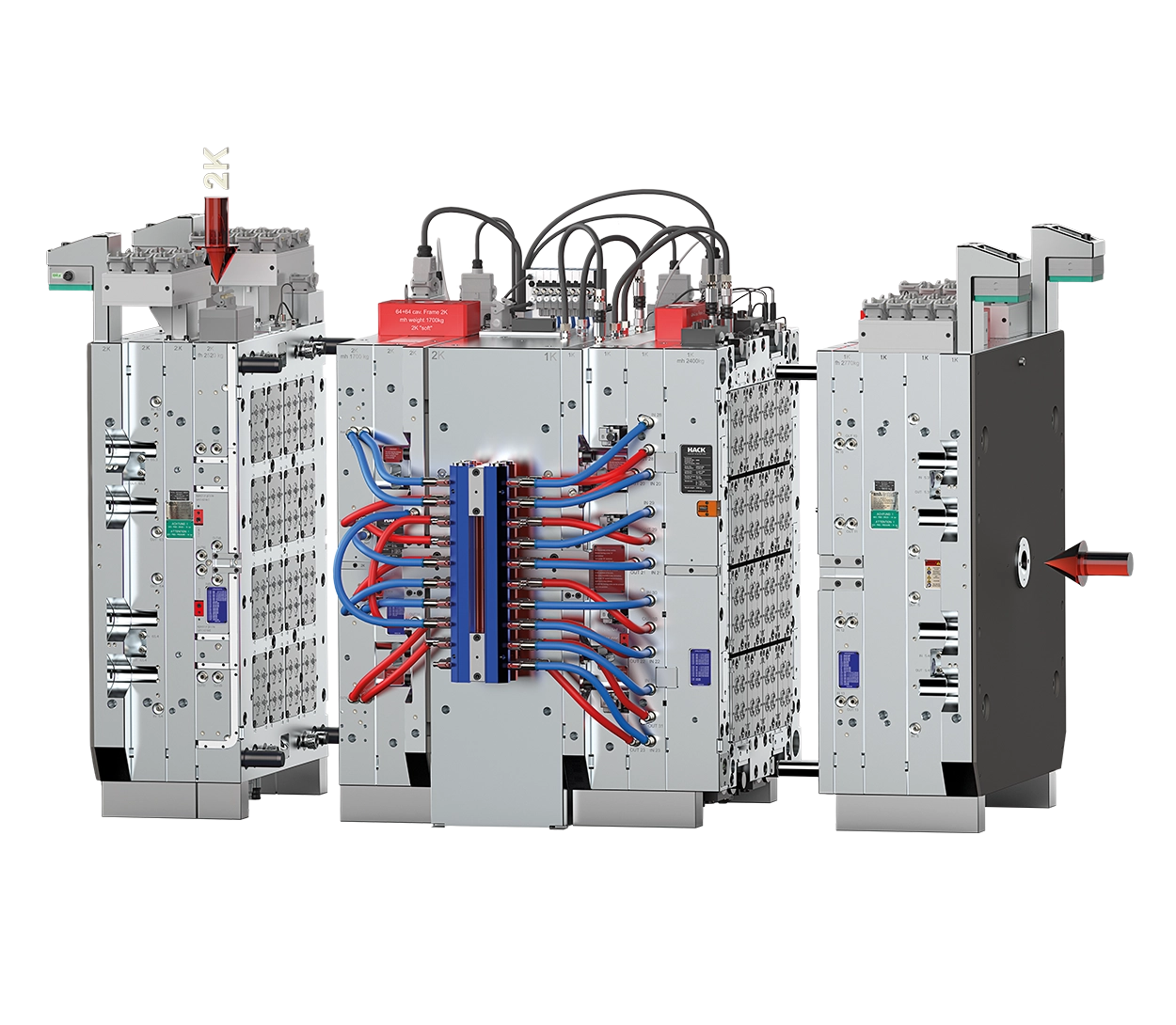

Variotwinstack

Moldmaking for maximum flexibility and availability

With our innovative variotwinstack technology and the combination of an injection molding machine equipped with two aggregates, it becomes possible to process different materials on every parting line – without any limitations in process or material selection.

Thanks to the separated process control, even different shot weights can be achieved with ease.

The intelligent control of the central block, fully integrated into the machine control system, ensures unrestricted accessibility: extraction grippers and other peripheral equipment are not obstructed by steep-thread spindles or rack-and-pinion systems.

The highlight: the complexity of conventional stack molds is eliminated, as the system essentially consists of two single-face molds.

This significantly reduces maintenance efforts and setup times.